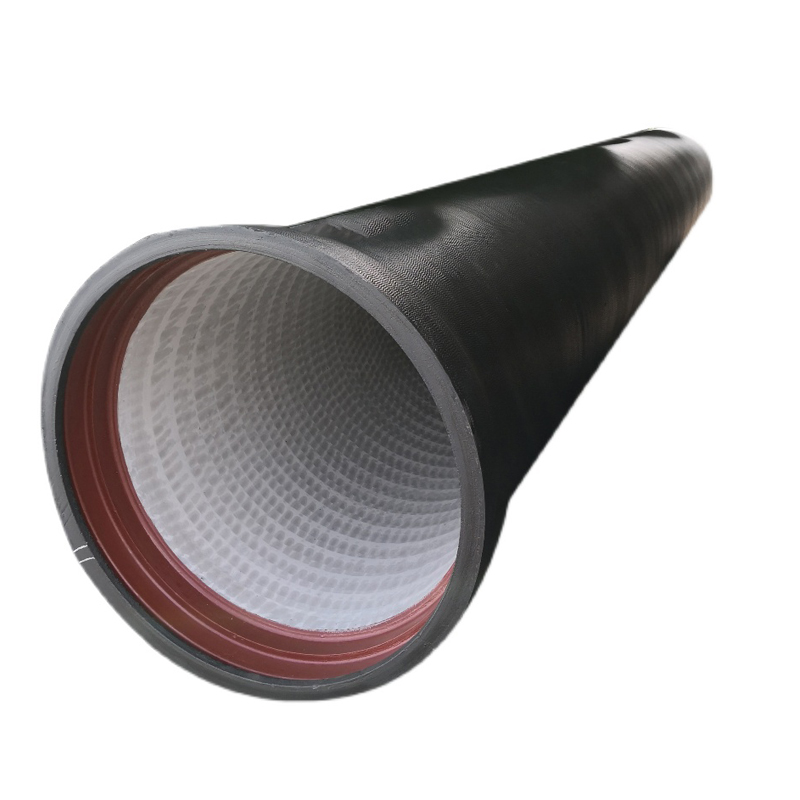

Ductile iron pipe production process involves several steps. Firstly, raw materials such as iron ore, scrap iron, and coke are melted in a blast furnace to produce molten iron. Next, the molten iron is poured into a ladle and treated with magnesium to convert it into nodular graphite. The molten iron is then poured into molds and allowed to cool and solidify, forming the ductile iron pipes. After cooling, the pipes are removed from the molds and undergo various finishing processes such as cutting, grinding, and coating to meet the required specifications.

Ductile iron pipes are commonly used in various environments due to their durability and strength. They are resistant to corrosion and can withstand high pressure and heavy loads, making them suitable for use in water supply systems, sewerage systems, and industrial applications. These pipes are also known for their flexibility and can be easily installed in different terrains, including rocky and uneven surfaces. Additionally, ductile iron pipes have a long lifespan and require minimal maintenance, making them a cost-effective choice for infrastructure projects.